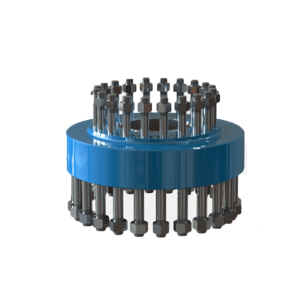

Weld Neck Flanges are pipe flanges attached by welding the pipes to the neck of the flanges which is transfers stress from the flange to the pipe instead. It also reduces the stress concentration from the base of the hub. Welding neck flanges remove stress concentration and allow full working pressure and they are often used for high pressure applications.

The weld neck flanges are manufactured according to API 6 specification. The inside diameter of the flange is designed to match the pipe’s inside diameter. Weld neck pipe flanges are typically provided with a raised face, flat face, or RTJ facing.

API 6A Type 6B and Type 6BX Weld neck flanges from forged alloy steel AISI4130. API 6A flanges are designed to join pipes together, increase support strength, or block off a pipeline. Type 6B flanges are of the ring joint type and are not designed for face-to-face make-up. The connection make-up bolting force reacts on the metallic ring gasket. Type 6BX flanges are designed with a raised face thus preventing damage to the flange and gasket.

| Description | Weld Neck Flange, Welding Neck Flange, WN Flange |

|---|---|

| Size | 1-13/16″ – 26-3/4″ |

| Working Pressure | 2000PSI, 3000PSI, 5000PSI, 10000PSI, 15000PSI, 20000 PSI |

| Material | AISI 4130(forged)/ SUS316/Inconel 625 |

| Face | FF, RF, RTJ |

| Connection | bolted or studded |

| Temp Class | L-U |

| Material Class | BB, CC, DD, EE, FF |

| Product Specification Level | PSL1, PSL2, PSL3, PSL4 |

| Performance Requirement | PR1, PR2 |

| Standards | API 6A, NACE MR0175, ISO 9001, ISO14001, ANSI |

| Application | Wellhead, Manifold, Shipbuilding, Pipe Projects etc |

| Performance Requirement | PR1, PR2 |

| Standards | API 6A, NACE MR0175, ISO 9001, ISO14001, ANSI |

| Application | Wellhead, Manifold, Shipbuilding, Pipe Projects etc |

Reviews

There are no reviews yet.