When operating pressure is 2000 psi, BOP stack will at least consist Annular Preventer, Ram Preventers, Drilling Spool. Annular preventer is installed on the top of the wellbore, while Ram preventers are located below the annular preventer.

Annular BOP

Annular blowout preventer (Annular BOP) is a special mechanical device used to seal, control, and monitor oil & gas well. Annular BOP is placed on the top of ram preventers. It is called annular due to its structure; it surrounds top of the wellbore in a shape of a ring or an annulus.

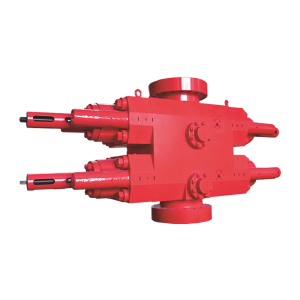

Ram BOP

Ram blowout preventer (Ram BOP) is a special assembly used during drilling as part of blowout prevention system. The shut-off valves in ram preventers close by forcing or ramming themselves together. Ram BOPs close the well by rams which operate in unison and actuated by hydraulic cylinders. Ram BOP has several types of rams, such as pipe ram, blind ram, shear ram and blind shear ram.

Drilling Spool

Drilling Spool is a mechanical device designed to connected wellhead with ram BOP or connect Double Ram BOP with Single Ram BOP, as well as provide means of mud circulation trough smaller-size nozzles, one for kill line, another for choke line.

Reviews

There are no reviews yet.