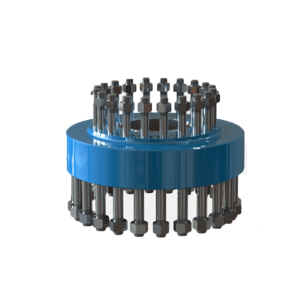

The Blind Flange is a kind of wellhead adapter flange used in oilfield wellhead service. The blind flange is made of high quality AISI4130 forged alloy steel in accordance with API6A standards.The blind flange size ranges from 1-13/16″ to 26-3/4″ and pressure up to 20000PSI. For sour service, all ring grooves can be inlaid with stainless steel SS316 or inconel 625 for better protection.

Often a blind flange is inserted into a pipeline when a repair is required further up the line. This allows the flanges down stream to be disconnected without fear of losing liquid. Usually this type of blockade is used when adding another line onto an existing pipeline or when a new valve is being added. This blockade is also used to shut down a line when it is no longer needed. Without the blind flange, it would be difficult to perform maintenance or repairs on a pipeline. The flow would need to be shut off at the nearest valve, which could be miles away from the repair area. Compared to expensive valves, the blind flange is a much more economical way of sealing a pipe.

| Size | 1-13/16″ – 26-3/4″ |

|---|---|

| Working Pressure | 2000PSI, 3000PSI, 5000PSI, 10000PSI, 15000PSI, 20000 PSI |

| Material | AISI 4130(forged)/ SUS316/Inconel 625 / 410 Stainless Steel |

| Face | RTJ, FF, RF |

| Connection | Bolted or Studded |

| Surface Treatment | Anti-Rust Oil, Transparent/Yellow/Black Anti-Rust Paint, Zinc, Hot Dipped Galvanized. |

| Temp Class | L-U |

| Material Class | BB, CC, DD, EE, FF |

| Product Specification Level | PSL1, PSL2, PSL3 |

| Performance Requirement | PR1, PR2 |

| Standards | API 6A, NACE MR0175, ISO 9001, ISO14001, ANSI |

Reviews

There are no reviews yet.