Coiled Tubing BOP is an important well control unit against overflow (oil, gas and water) and well blowout, thus to avoid resource waste, protect equipment and human safety. It plays an important role in applications such as drilling, workover and testing.

Multiple configurations such as single ram, dual ram, quad ram and combi ram are available to suit different customer needs. Each coiled tubing BOP is performed strict strength and performance tests as per API 16A before delivery to ensure its safety and reliability.

We can offer customized design as per customer requirements.

Features

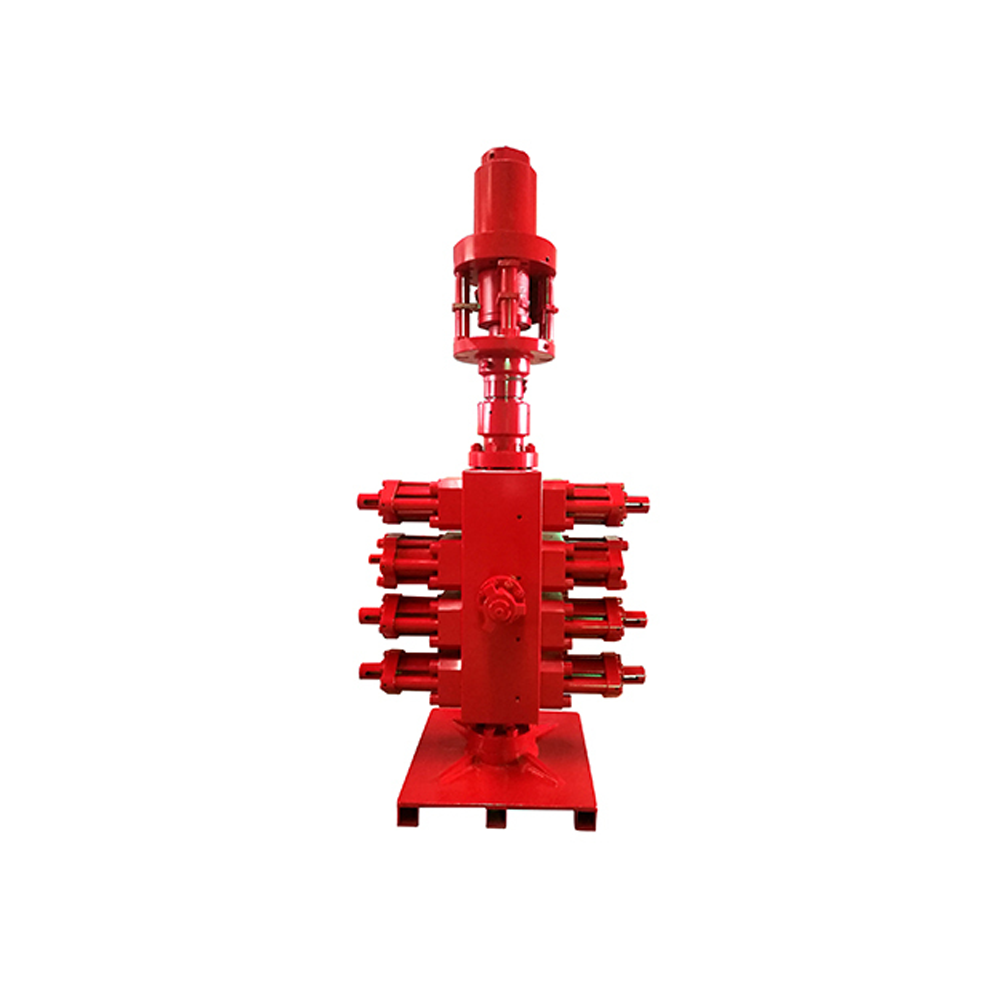

Coiled Tubing Quad BOP (internal hydraulic passage)

Ram open/ close and replacement adopt the same internal hydraulic passage, easy and safe to operate.

Ram running indicator rod is designed to indicate ram position during operation.

Innovative shear actuator eliminates the impact of wellbore pressure on shearing process.

Multicouplings allow fast and accurate engagement and disengagement of hydraulic control lines.

Combi BOP

Ram open/ close and replacement adopt the same internal hydraulic passage, easy and safe to operate.

Combi ram including shear-blind ram and pipe-slip ram feature simple operation and easy maintenance.

Ram position indicator rod is designed to indicate ram position during operation.

Open/close sign on the handwheel is easy to identify.

| Nominal Bore Diameter | 2-9/16″~5-1/8″ |

|---|---|

| Working Pressure | 2000psi~20000psi |

| Recommended Operating Pressure | 1500psi (2800psi for shear ram) |

| Side Outlet | 2-1/16“×10000psi |

| Size of Pipe be Sheared | OD 2-3/8“, wall 0.204” , CT110 class |

| Slip Rams’ Holding Weight | 40T (2“ coil tubing) |

| Temperature Class for Metallic Material | T75, T-20, T0 |

| Executive Standard | API 16A 4rd 、 API RP 16ST |

| Working Medium | petroleum, natural gas, water, mud, gas containing H2S, CO2 |

Reviews

There are no reviews yet.