Plug Valve is an important high pressure part for well service to allow and stop flow by plug rotation.

Plug valves are made from premium alloy steel, with special coating and heat treating process which greatly improves sealing

capabilities, anti-abrasive and corrosive resistance.

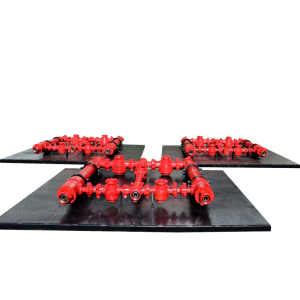

5 basic types (manual, hydraulic, electric, handwheel and manual & hydraulic actuators) are available to meet various needs

applicable to different services.

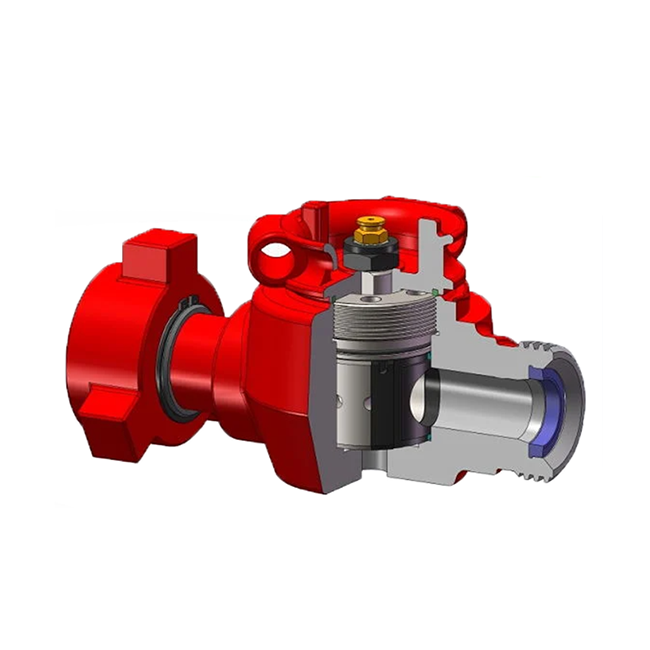

Working principle and structure characteristics:

mainly by the valve body, hand wheel, plunger, and other component parts.

Import and export have adopted 1502 from the previous form of connectivity (also customized according to customer needs), the valve body and between the cylinder liner tile with tile and through lining embedded into seals Cylindrical Seal.

Contrast between the tile and plunger seal cylindrical metal complexes, characterized with high precision, sealed reliable.

Note: 10000 psi high-pressure, can also more relaxed on or off valve.

| Rated working pressure | 69.0MPa~138.0Mpa(10,000psi-2000psi) | |

|---|---|---|

| Nonmetal size | 1″,1″x2″,11/2″,2″,2″x3″,3″, 4″ | |

| Temperature range | -29℃~121℃(PU), -46℃~121℃ (LU) | -20℉~250℉(PU), -50℉ ~250℉(LU) |

| Service | Standard, Sour Gas | |

| Working medium | Oil,natural gas,mud and gas containing H2S,CO2 | |

| Specification level | PSL 1- PSL4 | |

| Performance requirement | PR 1-2 | |

| Material class | AA,BB,CC,DD,EE | |

| Stanrard | API Spec 6A | |

| Application | Fracturing, Cementing, Acidizing, Testing Lines | |

Reviews

There are no reviews yet.