Oil well workover is a high-tech, high-risk work. The conventional oilfield workover rig has problems such complicated operating procedures and high labor intensity.

The system includes double monkey board pipes ranging robot, bolted beam system, machine hand, power catwalk, power elevator, hydraulic chuck, power control and monitoring system. The system uses one-button automated operation. The operation only needs one driller, one wellhead operator and one patrol personnel.

The oilfield automatic workover rig has a high degree of automation adopting modular integration and advanced robot closed-loop control technology. It functions as self-diagnosis, leakage and short circuit protection and fault alarming, etc. It has remote monitoring capability.

The automatic workover rig greatly increases the automation of workover operations, reduces the number of operators, decreases workers’ labor intensity. The technology is advanced, safe and reliable.

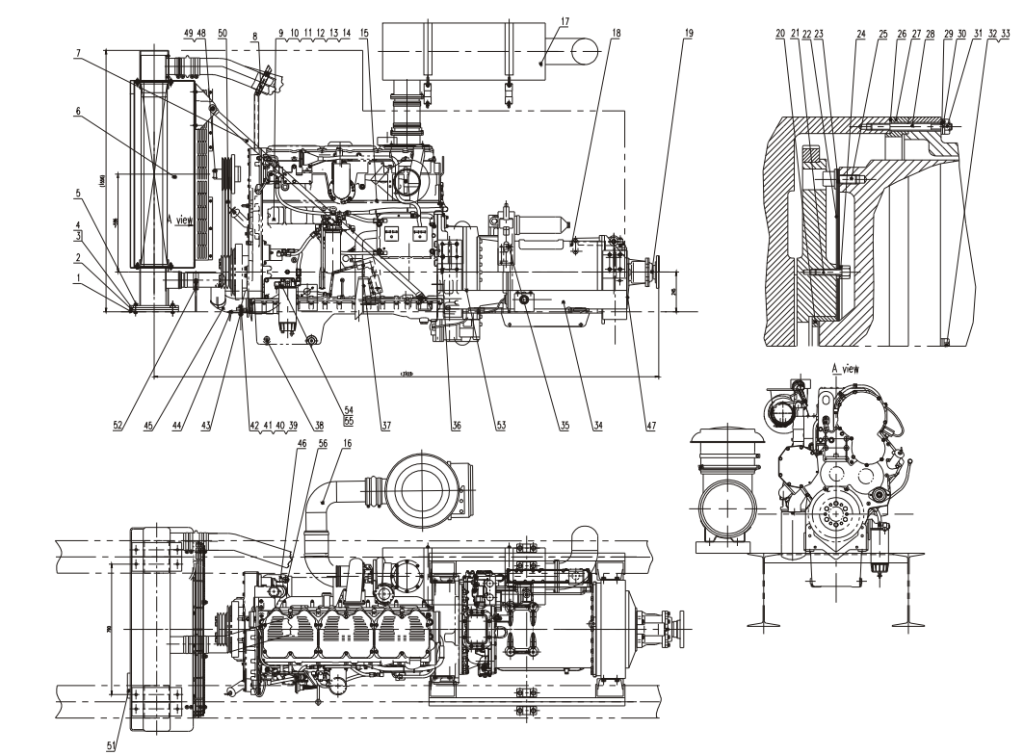

Power system Drawing NO.:Z01020000131AA)

| S/N. | Part. NO | Description | Qty | S/N. | Part. NO | Description | Qty |

|---|---|---|---|---|---|---|---|

| 1 | P6206407AA | Connection plate | 2 | 29 | 4313400010 | Flot wosher 10 | 12 |

| 2 | P1000410AA | Rubber pad | 2 | 30 | 4313400010 | Flot wosher 10 | 12 |

| 3 | 4301312055 | Bolt M12X55 | 8 | 31 | 4309300010 | Nut M10 | 12 |

| 4 | 4313000012 | Spring washer 12 | 8 | 32 | 5402650175 | 7/164-14UNC bol | 12 |

| 5 | 4309300012 | Nut M12 | 8 | 33 | 5402650176 | Wosher 7/16! | 12 |

| 6 | 5401050015 | Rodiator | 1 | 34 | Z01020000036AA | Support,engine torque-converter | 1 |

| 7 | Z01060000040AA | Support,water tank | 1 | 35 | Z01180000001A | Retarder installotion | 1 |

| 8 | Z01020300009AA | Support,cooled pipe | 1 | 36 | Z01080000006AA | Heat exchanger connection | 1 |

| 9 | P1300760AA | Engine and ball valve connector | 1 | 37 | Z01050000007AA | Throttle control mechanism | 1 |

| 10 | P1300764AA | Air inlet connector | 1 | 38 | Z01070000001AA | Ol droining device,engine oil sump | 1 |

| 11 | P1300763AA | Connector,check valve | 1 | 39 | 4303316060 | Bolt with hole M16X60 | 1 |

| 12 | P1300762AA | Connector,air pump | 1 | 40 | 4313000016 | Spring wosher 16 | 1 |

| 13 | P1300761AA | Air inlet connector | 1 | 41 | 4311700016 | Slotted nut M16 | 1 |

| 14 | P1100856AA | Bushing | 1 | 42 | 4314532030 | Cotter pin 03.2X30 | 1 |

| 15 | 2500150026 | Engine assembly<540HP) | 1 | 43 | P6200316AA | Rubber pac | 2 |

| 16 | Z01200100016AA | Air filter ond support | 1 | 44 | Z01020100004AA | Enqine installation beam | 1 |

| 17 | Z01100000066AA | Muffler installation | 1 | 45 | Z01090000002A | Schematic diagrom of fuel lines | 1 |

| 18 | 5401250025 | Cear box | 1 | 46 | P4100371AA | Adopter,wormer | 3 |

| 19 | P0200412AA | Flange disc | 1 | 47 | Z01020101012M | Oi filing port,torque converter | 1 |

| 20 | 5402650173 | Locoting line | 1 | 48 | P0200778AA | Connection flonge | 1 |

| 21 | 5402650105 | Bolt | 12 | 49 | P2201224AA | Bolt | 6 |

| 22 | 4900450024 | Flexible steel piece | 1 | 50 | 1100850202 | Enqine belf | 3 |

| 23 | 4900450023 | Flexible steel piece | 4 | 51 | 5402650330 | Fuel radiato | 1 |

| 24 | 4900450025 | Shim plate | 1 | 52 | Z01020300004AA | Support,air out cooled pipe | 1 |

| 25 | 5402650174 | Hex bol | 12 | 53 | Z01020400145AA | Spore parts of W5610AR transmission | 1 |

| 26 | 5402650123 | Sealing line | 2 | 54 | P2001095AA | 9/16”plug | 5 |

| 27 | 5402650452 | Connection ring | 1 | 55 | P1300001M | M18X1.5-9/16'connector | 2 |

| 28 | P2200176AA | Stud boll | 21 | 56 | P4100100AA | 22 hose connector | 5 |

Reviews

There are no reviews yet.